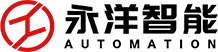

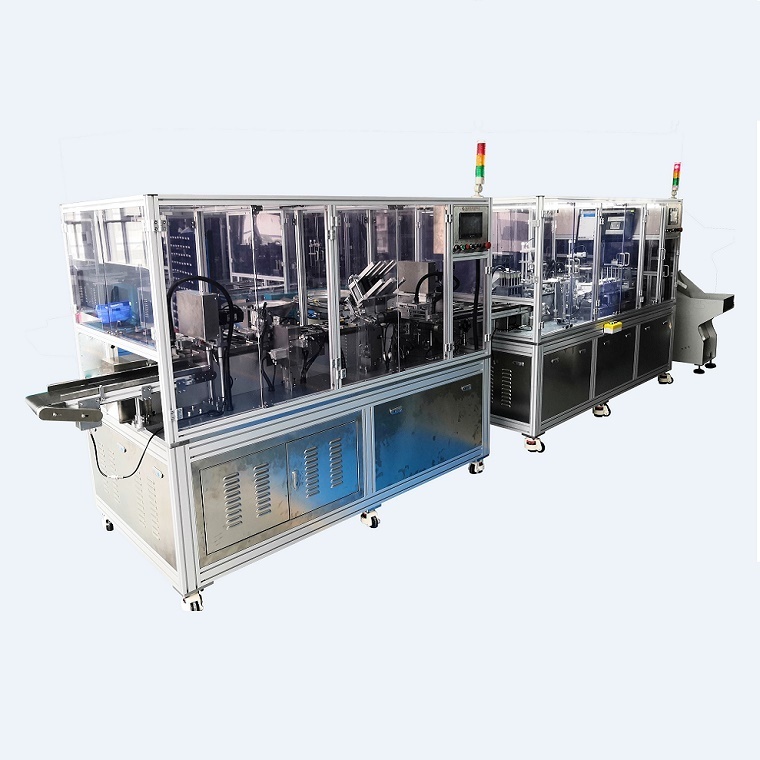

Assembly plan for customized reagent card packaging production line equipment

Reagent card packaging production line Yongyang Intelligent adopts a European-style high-rigidity structure. It has functions such as intelligent picking and defective product removal. Yongyang Intelligent is a technology company integrating the research and development, design, production, and sales of industrial automation equipment. For many years, the company has accumulated rich experience in the automation equipment industry, providing comprehensive intelligent manufacturing solutions for numerous customers and customizing various non-standard special machines according to the actual needs of customers. Giving full play to its own characteristics of "specialization", "precision", and "excellence", the company keeps in mind the business philosophy of "customer first, quality first", providing satisfied products and services to a wide range of customers and receiving unanimous praise from customers at home and abroad.

The current reagent card packaging production line is one of the products assembled by Yongyang Intelligent in its new working environment in Huizhou.

Assembly part:

Intelligent part: It adopts advanced high-performance PLC combined with touch screen control, which is simple to operate; it adopts frequency conversion speed regulation, which is energy-saving.

Mechanical linkage part: It adopts an encoder combined with a precision mechanical cam to utilize unified active power transmission, which can effectively improve work stability and machine durability.

Automatic feeding part: It adopts an automatic vibration feeding method, and the robotic arm is precisely installed, which effectively improves the feeding and installation effect.

Other auxiliary parts: Yongyang Intelligent will choose to use according to customer requirements.

The main accessories include solenoid valves (SMC) / photoelectric sensors (Keyence) / motors (Tianyang) / PLC (Mitsubishi) / relays (Schneider / AUTONICS) / proximity sensors (Balluff / AUTONICS) / cylinders (SMC / AIRTAC) / encoders (KOYO) / inverters (Shilin / BES) / bearings and some standard parts (IKO / MISUMI), etc.

Its process flow is convenient to use, as follows:

Bottom shell lifting and feeding → Positive and reverse detection → Positive and reverse adjustment → Front and rear direction detection → Front and rear direction adjustment

→ Reagent large plate cutting →

Top cover lifting and feeding → Positive and reverse detection → Positive and reverse adjustment → Front and rear direction detection → Front and rear direction adjustment

Intelligent camera takes photos to detect and cut reagent strips → Reagent strip installation → Intelligent camera detects whether the installation is in place → Top cover displacement installation → Top cover and bottom shell pressing → Reagent card rolling and output → Conveying to the packaging line → Reagent card feeding → Reagent card detection → Desiccant feeding → Desiccant detection → Aluminum foil bag feeding → Aluminum foil bag detection → Bagging → Sealing and welding → Finished product output

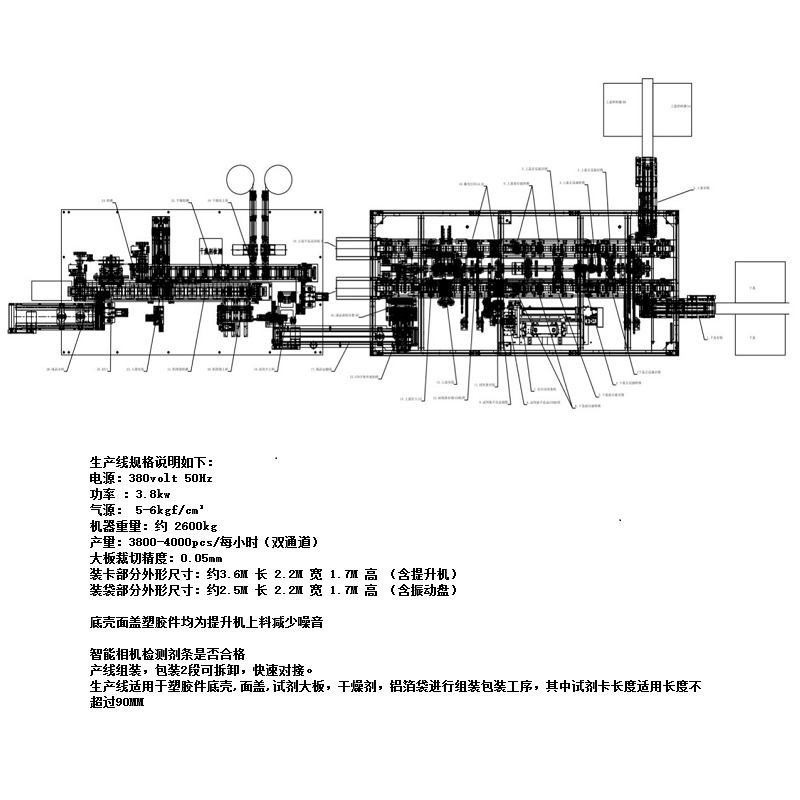

Four production line plane diagram:

Production line specifications are as follows:

Power supply: 380volt 50Hz

Power: 3.8kw

Air source: 5-6kgf/cm²

Machine weight: about 2600kg

Output: 3800-4000pcs/hour (dual channel)

Large plate cutting accuracy: 0.05mm

External dimensions of the card loading part: about 3.6M long, 2.2M wide, 1.7M high (including the elevator)

External dimensions of the bagging part: about 2.5M long, 2.2M wide, 1.7M high (including the vibrating plate)

The bottom shell and top cover plastic parts are all fed by the elevator to reduce noise.

Intelligent camera detects whether the reagent strip is qualified.

The production line assembly and packaging sections can be disassembled and quickly connected.

The production line is suitable for the assembly and packaging process of plastic bottom shells, top covers, reagent large plates, desiccants, and aluminum foil bags. The applicable length of the reagent card does not exceed 90MM.

More Information

Assembly plan for customized reagent card packaging production line equipment